最新ニュース

製品カテゴリ

ホット 製品

-

チャンピオンシップボランタインのプレミアムテーブルテニステーブル

このプレミアムテーブルテニステーブルは選手権に適しています。 ITTFとNSCCによって承認されました。 シルバーアンダーキャリッジ+ブルーライト

続きを読む -

トーナメントVolant Dream 2の公式卓球テーブル

ダブル・フィッシュ・スポーツがデザインした国際大会のための公式ピンポン表Volant Dream 2

続きを読む -

Competitonsの公式卓球テーブルXIANGYU 328

プレミアムダブルFoldableポータブル卓球テーブル、コンパクトなデザイン 新しい折り畳みシステムは、テーブルの保管と移動中の怪我のリスクを最小限に抑えます。 ITTFは卓球台を承認した。

続きを読む -

ワールドツアー99-45Bのための公式の耐久性のある卓球テーブル

ITTFは国際大会のための公式の耐久性のある卓球台を承認した。 テーブルボードの厚さ:25mm トーナメント品質 - このプロフェッショナルレベルのテーブルは、最高レベルの競争のために設計されています。 家族のために完璧な - すべての年齢のためのプレミアムプレイを提供します。頭を下げて行くか、個々の練習のために折りたたむ。 2インチの重いゲージスチールサポートは、最も困難な課題を抱えています。あなたのゲームルーム、デン、またはジムのための中心的なピース。 簡単な組み立て - 簡単なアセンブリで数分で演奏を開始します。高品質のネットには、簡単に取り付けられるロッククランプが装備されています。

続きを読む -

ベストクオリティダブルフィッシュV40 + Volant 3 Stars卓球

ダブルフィッシュV40 + Volant 3スター卓球ボールは、ITTF最新のT3技術基準に確約されています。

続きを読む -

二重魚QIJIオールラウンド卓球ブレード

二重魚QIJIオールラウンド卓球ブレード、これは、ベストセラー卓球テーブルテニスブレードです 伝統的なallroundプレーヤーに最適

続きを読む

ダブルフィッシュの起源を辿る - 広州卓球工場の発展(第1部)

中華人民共和国の建国以来、広州は国家経済社会発展5カ年計画を実施し、社会主義の工業化と近代化のプロセスを着実に推進してきました。この期間、広州は社会主義経済システムを初めて確立し、社会主義建設の全面的な推進の基礎を築きました。

1959年秋、広州東部の屯頭寺②の荒れ果てた茅葺き小屋で重要な支部委員会会議が開催されていた。支部長の廖宏洛は、地区委員会の決定を伝え、中部地区③の食品、文化、教育産業の30余りの工場の作業を中止し、この地に化学原料生産基地を建設することを決定した。会議では全員が協議し、各工場に残された土木設備と労働者を集めて、独立会計の新しい工場を設立した。すぐに上司は彼らの提案に同意し、「成功のみを許し、失敗は許さない」という厳しい指示を下した。こうして、「成功食品化学工場」という名前が生まれた。

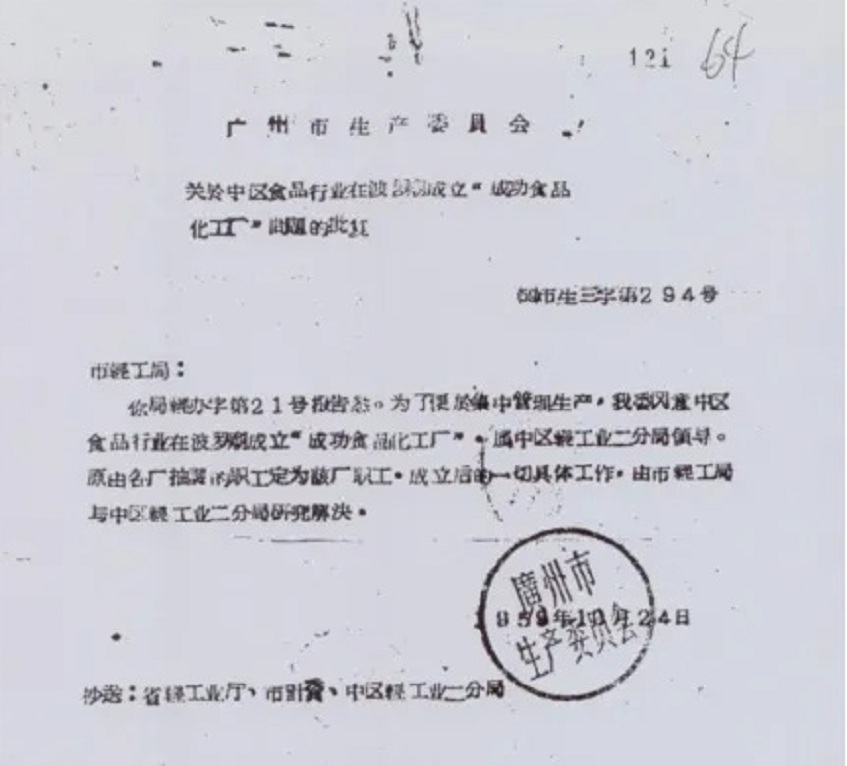

広州市生産委員会からの成功食品化学工場設立に関する回答

1960年3月、新生工場は北岸⑤のポロ寺④の新敷地に移転することを決定した。荒れた不毛の丘の中腹、貧弱な「基礎」を持つ新工場は、「頭上には空、足元は荒野」の苦難に直面していた。このような状況で工場を運営できるのだろうか?労働者は言った。「出来合いの食事を食べる人は骨が軟弱になる。どんなに大変でも、最初にドゥントウジに来たときの茅葺き小屋に住み、泥の上に寝るほど大変ではない。

「①本文の内容は主に成功卓球工場の歴史資料と『広州城史』第5巻(上)303~304ページに基づいて編集されています。 ②

1980年代の広州成功卓球工場の元工場長、李周昌の回想によると、東郊屯頭地は黄浦区南港付近にあります。

③1960年に中央区が廃止され、中央区の大部分は現在の越秀区に割り当てられ、一部の地域は茘湾区と海珠区に割り当てられました。

④南海寺、東寺とも呼ばれるポロ寺は、広州市黄浦区廟頭村にあり、隋代開皇14年(594年)に建てられ、1400年以上の歴史があります。

⑤工場敷地は珠江河口に近いため、周囲の海水の成分が化学原料の生産に影響を与えるため、より適した場所に工場を移転することになりました。

There are ways to deal with poverty. If there is no house, build it yourself!" So, they transported all the building materials from Duntouji - whether it was a straw shed, bricks and tiles, or a stove, or even a newly planted peach tree - across the river without omission, and started to build a new factory on this barren land. On this barren hillside, cadres, workers, and hundreds of heroes were engaged in base construction. Those who burned lime, carried sand and water, moved bricks to build walls, and nailed metal frames... During the day, it was steaming; at night, it was bustling. Everyone was united, and the soil turned into gold, and the factory buildings and dormitories were built.

Although the factory building was built, it still faced many challenges. But the workers were not afraid of difficulties and began to use local methods to produce chemical products to meet the urgent needs of industrial production at that time. They set about producing basic chemical raw materials such as hydrochloric acid, pure sulfur, ethanol, monomer flavors, barium sulfide and hydrosulfuric acid, and supplied them to many factories including the Asia Soda Factory to support the development of Guangzhou's industry.

At this time, the table tennis sport in New China had gradually developed, constantly pushing the domestic table tennis sport to a new peak.

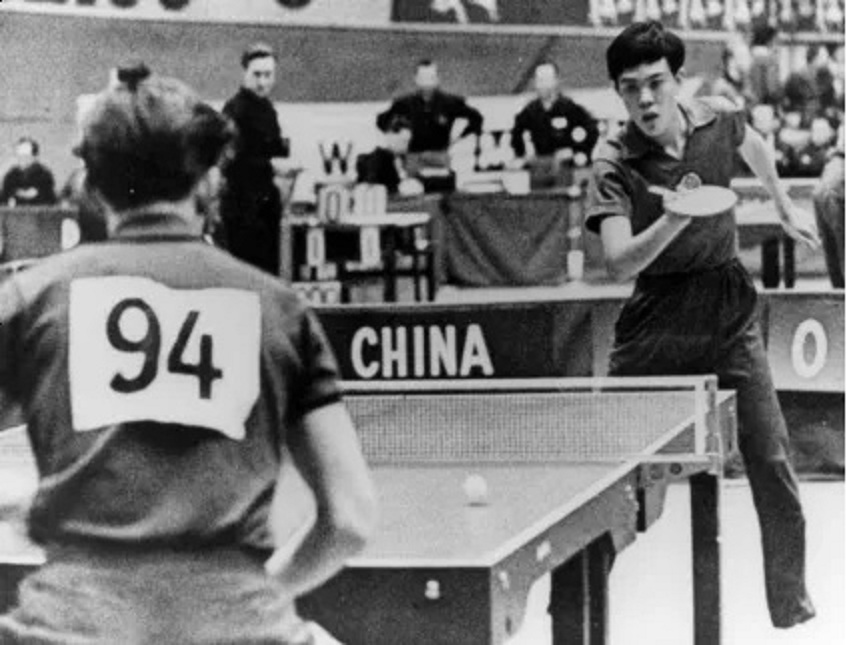

In 1959, the world was shaken by a Chinese athlete. On April 5 of that year, the 25th World Table Tennis Championships was held in Dortmund, the former West Germany. The 21-year-old table tennis player Rong Guotuan defeated many world players in succession, and finally faced the Hungarian veteran Sido who had won the world championship nine times. Rong Guotuan played steadily after losing the first game, and finally won three games in a row, winning the men's singles world championship for China. This is the first world championship since the founding of New China.

The 25th World Table Tennis Championships, Rong Guotuan is in full swing

Almost at the same time as Rong Guotuan won the championship, the International Table Tennis Federation agreed to host the 26th World Table Tennis Championships in Beijing. After the news came out, people rushed to tell each other, and all parties showed concern and support. Welcoming the "26th" and playing well in the "26th" has become a major event across the country. As a result, the table tennis craze swept across China, and the demand for table tennis equipment increased day by day.

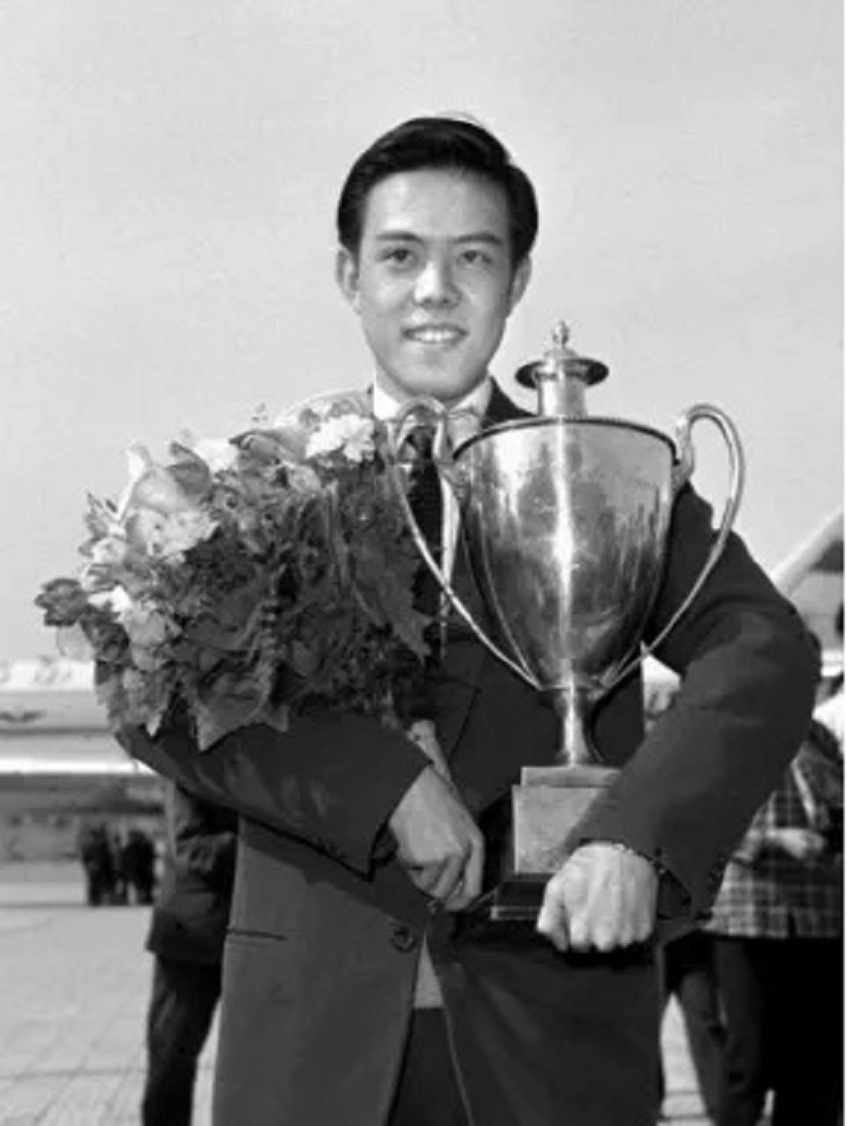

China's first world champion Rong Guotuan

In 1960, in response to Chairman Mao's call for "developing sports and strengthening the people's physique" and to meet the people's need for table tennis when developing sports, in September of that year, the superiors decided that the future product task of Chenggong Factory would be to produce table tennis. The factory name was changed to Chenggong Table Tennis Factory, and it was decided to integrate a table tennis trial production team of Guangzhou Guoqun Musical Instrument Factory ⑥ into it. Unexpectedly, this production conversion decision determined the fate of the birth of the first professional table tennis factory in Guangzhou, and even had a profound impact on the development of Chinese table tennis equipment!

The appearance of the factory near the Polo Temple in the last century

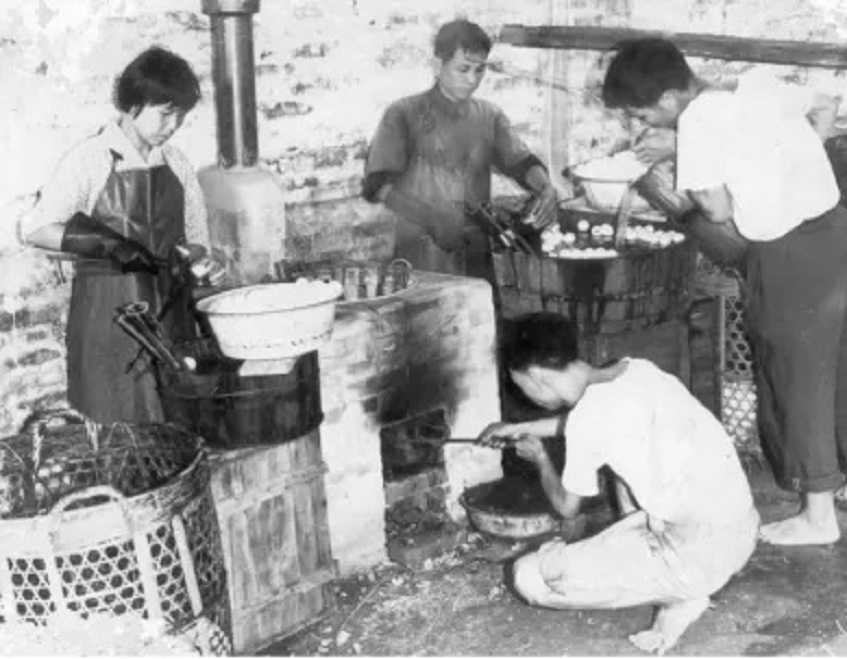

When the Chenggong Table Tennis Factory received the task of switching to the production of table tennis balls, it faced many difficulties: first, it had no technology to produce table tennis balls; second, it had no machinery and equipment, only a few simple tools such as vises, hand drills, and broken bellows; third, it had no industrial water, only a drinking well; fourth, it had no suitable factory buildings, only four borrowed earthen houses for temporary residence. All the employees of the factory carried forward the spirit of "self-reliance and hard work", relying on simple tools to make parts and equipment; dig channels and build pools to draw mountain water, and use cars to draw river water during droughts; build earth stoves, borrow large pots, and use boiling water to "cook" table tennis balls⑦

"⑥According to the "Guangzhou City Annals", in the early 1950s, Guangzhou Guoqun Musical Instrument Factory once produced toy table tennis balls, with a monthly output of about 50,000.

⑦The original table tennis ball process: First, the 0.55 mm thick raw material is cut into discs through a punching process. Then, these discs are heated in hot water to soften, and then placed in a pressing mold and pressed into two hemispherical shapes with edges. After the initial forming is completed, the edge rings of the two hemispheres are cut off to ensure the neatness and uniformity of the edges. Subsequently, the two hemispheres with the edge rings removed are precisely bonded by using a special solvent, and the bonded spheres are soaked in warm water for maintenance. Finally, Put the bonded sphere into the mold and heat it in a medium with a temperature higher than 100 degrees (such as water or wax solution) to eliminate the bonding seams and ensure the overall strength and shape of the sphere. The process of "boiling" ping-pong balls refers to the last step, which is to heat it in a medium with a temperature higher than 100 degrees (such as water or wax solution) to eliminate the bonding seams. "

Early ping-pong ball production

当時はブランド商標も明確な品質基準もなかったが、このピンポンボールは、ダブルフィッシュの先輩たちの数え切れないほどの努力と汗を体現し、「自立と努力」という思想の光で輝き、ついに成功を収めた。

+8620-84319554

+8620-84319554 +8620-84328948

+8620-84328948

+86 13829778212

+86 13829778212