最新ニュース

製品カテゴリ

ホット 製品

-

チャンピオンシップボランタインのプレミアムテーブルテニステーブル

このプレミアムテーブルテニステーブルは選手権に適しています。 ITTFとNSCCによって承認されました。 シルバーアンダーキャリッジ+ブルーライト

続きを読む -

トーナメントVolant Dream 2の公式卓球テーブル

ダブル・フィッシュ・スポーツがデザインした国際大会のための公式ピンポン表Volant Dream 2

続きを読む -

Competitonsの公式卓球テーブルXIANGYU 328

プレミアムダブルFoldableポータブル卓球テーブル、コンパクトなデザイン 新しい折り畳みシステムは、テーブルの保管と移動中の怪我のリスクを最小限に抑えます。 ITTFは卓球台を承認した。

続きを読む -

ワールドツアー99-45Bのための公式の耐久性のある卓球テーブル

ITTFは国際大会のための公式の耐久性のある卓球台を承認した。 テーブルボードの厚さ:25mm トーナメント品質 - このプロフェッショナルレベルのテーブルは、最高レベルの競争のために設計されています。 家族のために完璧な - すべての年齢のためのプレミアムプレイを提供します。頭を下げて行くか、個々の練習のために折りたたむ。 2インチの重いゲージスチールサポートは、最も困難な課題を抱えています。あなたのゲームルーム、デン、またはジムのための中心的なピース。 簡単な組み立て - 簡単なアセンブリで数分で演奏を開始します。高品質のネットには、簡単に取り付けられるロッククランプが装備されています。

続きを読む -

ベストクオリティダブルフィッシュV40 + Volant 3 Stars卓球

ダブルフィッシュV40 + Volant 3スター卓球ボールは、ITTF最新のT3技術基準に確約されています。

続きを読む -

二重魚QIJIオールラウンド卓球ブレード

二重魚QIJIオールラウンド卓球ブレード、これは、ベストセラー卓球テーブルテニスブレードです 伝統的なallroundプレーヤーに最適

続きを読む

起源を辿る | 広州卓球工場の発展(第2部)

1960年秋以来、成功卓球工場は2年以上をかけて技術革新に取り組み、1963年末までに工場の主な生産工程を基本的に機械化し、製品の生産量と品質を向上させ、製品の輸出を開始しました。1963年の生産量は320万台で、1960年の78万台の3倍以上となり、そのうち58,400台が輸出されました。

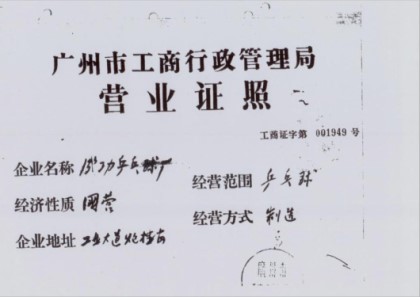

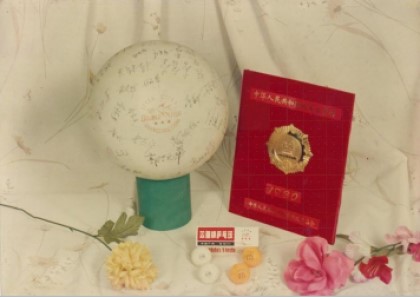

成功卓球工場の営業許可証

①本記事の内容は主に成功卓球工場の歴史資料と『広州城史』第5巻(第1部)303~304ページに基づいています。

しかし、成功卓球工場の生産が好調に推移する中、ポロ寺地区の水資源不足が新たな問題となり、さらなる発展を阻むこととなった。結局、上層部は水不足の問題を解決し、生産規模をさらに拡大するため、成功卓球工場を河南工業大道②の隣のパオロウガンに移転することを決定した。この移転は、成功工場の発展における新たな章の始まりとなった。

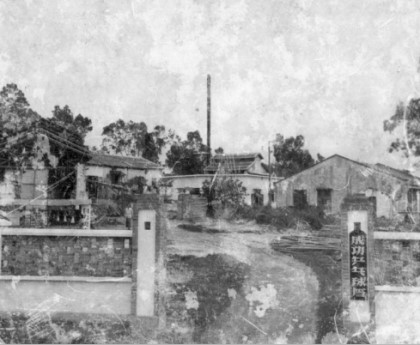

成功卓球工場が海珠区燕子港に移転

②河南工業大道の隣の宝狼港は、現在海珠区燕子港エリアです。1952年から広州市「河南」郊外は広州の重要な工業基地として建設され、この大道はかつて広州の産業の中心地であり、多くの国内初の製品を生み出しました。全盛期には、全長5.5キロメートルの工業大道で万宝冷蔵庫、虎頭電池、五洋自転車など、全国で人気の製品が生産されていました。成功卓球工場が移転した土地は元々陶磁器工場で、基本的な工場設備がすでに整っており、生産拡大に便利でした。上位部門の強力なサポートにより、成功卓球工場は土地を購入して建設を開始し、将来の発展のための確固たる基礎を築くことができました。

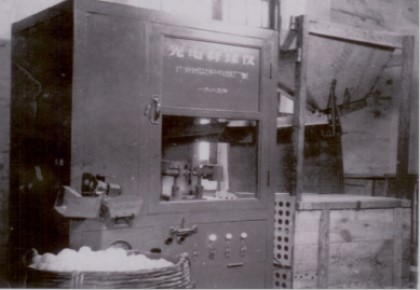

1965年、成功卓球工場はわが国初の光電式ボール計量機を開発し、さらなる成功を収めました。その後、自動重心測定機、自動商標印刷機、自動縁取り機、自動測定機などを次々と製造し、全国の同業他社に先駆けて半自動、自動卓球生産を実現しました。1966年、卓球ボールの生産量は1000万個を超えました。「文化大革命」の時期には、いくつかの工場を合併し、サイリスタも生産しました。

In 1965, Chenggong Table Tennis Factory pioneered my country's first photoelectric ball weighing instrument.

Automatic label printing machine developed by Chenggong Table Tennis Factory

In 1968, with the support and coordination of the local government, Chenggong Table Tennis Factory merged with Huada Badminton Factory③ and Zhendong Sports Goods Factory④ , significantly improving the productivity of the enterprise. Subsequently in 1969, the factory was renamed Guangzhou Sporting Goods Factory, marking the expansion of its product categories and business scope.

③According to the "Chronicles of Guangzhou City", the production of badminton in Guangzhou began in the early 1950s. With the rise of badminton, the production households continued to develop and gradually organized themselves. In 1956, the Yongjian Badminton Production Cooperative and the Yufeng Production Cooperative were formed. In 1960, the Yongjian Society was renamed the Huada Badminton Factory, with 100 employees. In 1964, the World Games brand badminton of the Yufeng Society was rated as a famous brand product in Guangzhou. During the "Cultural Revolution", all badminton production cooperatives were merged into the Chenggong Table Tennis Factory.

④Zhendong Sports Goods Factory mainly produced wooden-handled skipping ropes, table tennis nets, and volleyball nets. Before the merger, the two factories were located on the streets in the urban area, with scattered and narrow factory buildings (all old residential buildings), making material transportation and management extremely inconvenient. The merger improved the production conditions of such products. This article is compiled based on the oral narration of the retired leaders of Guangzhou Table Tennis Factory.

In 1972, the company was renamed Guangzhou Table Tennis Factory. In the same year, Guangzhou Table Tennis Factory introduced the innovative wax expansion method, replacing the old steaming process for producing close-seam balls, which doubled the work efficiency. The introduction of this technology not only improved production efficiency, but also made Guangzhou Table Tennis Factory the first company in China to achieve full mechanization of close-seam ball production.

Table tennis ball expander from the mid-1970s

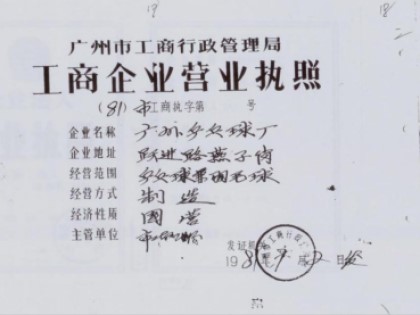

Guangzhou Table Tennis Factory Business License

In 1974, after five months of unremitting efforts and more than 130 precision tests, the Guangzhou Table Tennis Factory successfully developed China's first hard table tennis ball. This achievement marked a major breakthrough in China's table tennis manufacturing technology. The product was subsequently named "Shuangyu Brand". In 1979, this table tennis ball was officially approved by the International Table Tennis Federation and became the designated ball for international official competitions.

In 1980, "Double Fish" brand table tennis balls were officially rated as a national famous trademark and won the National Gold Award in the same year.

Doublefish table tennis won the national gold medal certificate

In 1981, with the booming domestic and foreign markets for badminton, the Guangzhou Table Tennis Factory restarted the production of badminton with the formal approval of the competent authorities. It focused on creating special balls for high- and mid-end competitions, strictly selected high-quality white goose feathers, and used imported cork and artificial leather as ball head materials to produce badminton with excellent whiteness, strong flight stability, and precise landing points. All products were sold to the Japanese market.

From 1986 to 1990, the annual output of badminton achieved an average high growth rate of 31%. In 1989, advanced Japanese production equipment was introduced, which greatly improved the production capacity and reached an annual production capacity of 24 million. In 1987, the Jinque brand badminton in the domestic market was rated as a high-quality product by the Ministry of Light Industry, and in 1990 it won the official certification of the national competition ball, marking the full recognition of product quality and technical level.

In 1986, as sales continued to expand, Guangzhou Table Tennis Factory set up branch factories in Zengcheng and Huaxian (now Huadu District, Guangzhou), focusing on producing mass-market table tennis balls to meet domestic market demand, while the main factory was committed to producing mid- and high-end table tennis balls for export. In 1987, total production soared to 63.02 million, of which 54.82 million were sold to overseas markets, generating US$2.18 million in foreign exchange revenue.

In 1988, the outstanding performance of Guangzhou Table Tennis Factory won the honorary titles of Provincial Advanced Enterprise and National Second-Class Enterprise. In 1990, Guangzhou Table Tennis Factory invested 2.5 million yuan in factory construction and technical transformation to further improve production capacity. In November of the same year, a new celluloid sheet plant was established in Zengcheng with an investment of nearly 2.57 million yuan. Through this series of transformation and expansion, the annual production capacity of table tennis balls doubled from 60 million to 120 million, making Guangzhou Table Tennis Factory one of the important bases for table tennis ball production in the world.

Guangzhou Table Tennis Factory in the 1990s

In 1994, the company relocated and expanded again⑤, requisitioned 50 mu of production land in Dabu Management District, Mayong Town, Dongguan City, relocated and renovated it, expanded its production scale, and achieved rapid improvement in production quality, laying a solid foundation for the company's sustainable development.

⑤卓球の生産原料であるセルロイドの主成分はニトロセルロースであるため、この材料は極めて燃えやすく、上海のダブルハピネス卓球工場や天津卓球工場での火災事故など、中国で多くの重大な火災事故を引き起こしました。1993年10月14日には、広州卓球工場でも火災が発生し、4,000平方メートルの建物が焼失しました。さらに、1990年代に燕子港周辺の住宅地が急速に成長し、その地域の安全上の危険性がますます顕著になりました。これを考慮して、広州卓球工場は、より高い安全基準と生産効率を確保するために、生産ラインを全面的に東莞に移すことを決定しました。

1990年代の東莞工場

1995年、 「Doublefish」ブランドの大きな影響力に基づき、広州卓球工場は正式に広州Doublefishスポーツ用品工場に社名を変更しました。

1998年2月26日、広州双宇運動用品工場は広州双宇運動用品グループ株式会社に合併されました。

+8620-84319554

+8620-84319554 +8620-84328948

+8620-84328948

+86 13829778212

+86 13829778212